|

Save up to 30% of your air-conditioning costs

|

The air-conditioning saver...

Energy efficiency: the smart answer to today's energy crisis! Most existing air conditioning units waste a significant part of the consumed electricity because they are not controlled in a smart way. Making these air conditioning systems more energy efficient is by far the quickest, most affordable and most effective way to reduce your CO2 emissions and lower your energy bill. And the good thing is: It's easy with an AIRCOSAVER! The AIRCOSAVER is an EPV Electronics Germany solution |

|

The AIRCOSAVER

Often copied, never reached. The AIRCOSAVER is the genuine original that has been setting the standard in this product category ever since the first generation AIRCOSAVER was introduced in 2001. Several competitors have tried to copy the AIRCOSAVER but have never invested a similar amount of R&D, testing and engineering. Benefits of the AIRCOSAVER Quick & easy to install

Higher savings & guaranteed cooling comfort due to improved software

Better protection for your aircon unit

Further product features

|

Air conditioning has a huge potential for efficiency improvements

Air conditioning is one of the largest energy consumers in the residential and industrial sector. Thousands of air conditioners put high demands on our electricity networks. On a smaller scale, air conditioning probably accounts for a significant part of your energy bill.

Many existing air conditioners use old and quite inefficient technology. Although improved technology has become available in more expensive systems (e.g. inverter technology), the payback time of these systems is still very long and most of this technology is not suitable as an easy and economical aftermarket fit to existing systems.

In the light of today's energy problems, global warming and since older and not so advanced aircon systems will be in use for many more years in large numbers, we have analysed various existing energy saving techniques for air conditioning systems and reviewed plenty of earlier research. The conclusion was that detecting the system's efficiency and switching the compressor accordingly is probably the only effective, pragmatic and economical measure to achieve a better energy efficiency. There is no "free lunch" with any retrofit, but these savings come at no or only very small decreases in cooling comfort.

Air conditioning is one of the largest energy consumers in the residential and industrial sector. Thousands of air conditioners put high demands on our electricity networks. On a smaller scale, air conditioning probably accounts for a significant part of your energy bill.

Many existing air conditioners use old and quite inefficient technology. Although improved technology has become available in more expensive systems (e.g. inverter technology), the payback time of these systems is still very long and most of this technology is not suitable as an easy and economical aftermarket fit to existing systems.

In the light of today's energy problems, global warming and since older and not so advanced aircon systems will be in use for many more years in large numbers, we have analysed various existing energy saving techniques for air conditioning systems and reviewed plenty of earlier research. The conclusion was that detecting the system's efficiency and switching the compressor accordingly is probably the only effective, pragmatic and economical measure to achieve a better energy efficiency. There is no "free lunch" with any retrofit, but these savings come at no or only very small decreases in cooling comfort.

Upgrade your air-conditioning unit

Shortcomings of typical air-conditioning units

A typical cooling cycle

When switched on, typical air conditioning systems operate continuously until the room thermostat senses the desired temperature and turns the system off. As the room warms up, the thermostat switches the air conditioner back on and the cycle repeats.

Most air-conditioning units are oversized for the majority of operating conditions

Air conditioning systems are usually dimensioned to cope with the extreme cooling demands of the few hottest days of the year (plus a safety margin).

However, in most operational conditions, this maximum output is not required and the system is oversized. So running the system continuously until the room thermostat switches it off means that the system operates with excess capacity most of the time.

When switched on, typical air conditioning systems operate continuously until the room thermostat senses the desired temperature and turns the system off. As the room warms up, the thermostat switches the air conditioner back on and the cycle repeats.

Most air-conditioning units are oversized for the majority of operating conditions

Air conditioning systems are usually dimensioned to cope with the extreme cooling demands of the few hottest days of the year (plus a safety margin).

However, in most operational conditions, this maximum output is not required and the system is oversized. So running the system continuously until the room thermostat switches it off means that the system operates with excess capacity most of the time.

|

A typical cooling cycle with excess capacity looks like this:

|

How the AIRCOSAVER improves energy efficiency

|

The aircon energy saver compensates the shortcomings of typical AC units and adds intelligence to your AC system

The AIRCOSAVER's sensor-driven software algorithms are designed to detect thermodynamic saturation and to optimize the compressor accordingly. When overcapacity is detected, the AIRCOSAVER switches the compressor off and avoids inefficient overcooling. Your unit switches into "saver mode". The fan keeps running and your system makes maximum use of the stored cooling energy in the heat exchanger. Once the stored energy is used up, the compressor can work efficiently again and is switched back on. The set room temperature is reached without the inefficient parts of the cooling cycle. This results in significant energy savings without compromising cooling comfort. Since the correct point to switch the compressor varies from unit to unit and changes with different weather conditions, the AIRCOSAVER is constantly monitoring the cooling status of your aircon unit and adapting its settings to ensure efficient operation of your air conditioning system at all times. Protecting your unit against short cycling Cycling the compressor too frequently in too short time intervals may harm the compressor and must be avoided. For this reason, the AIRCOSAVER features a built-in anti short cycling protection. Besides the continuous anti short cycling protection, the AIRCOSAVER also adds a delay upon power-on to your unit. This valuable feature protects your aircon unit against damages from short power outages like they are common in many developing countries. |

About the AIRCOSAVER - Installation

The AIRCOSAVER is designed to be installed into existing systems as an after market fit. Installation is simple and takes approximately 15 minutes (depending on local situations). A detailed step-by-step installation manual is provided with each AIRCOSAVER.

Installation overview

For clarity's sake the images below illustrate the installation of an AIRCOSAVER into a small window unit. However, the installation steps are basically the same for many other types of aircon units. The AIRCOSAVER is suited for a wide range of air conditioning types such as single-split systems, packaged units or small central aircon units.

Installation overview

For clarity's sake the images below illustrate the installation of an AIRCOSAVER into a small window unit. However, the installation steps are basically the same for many other types of aircon units. The AIRCOSAVER is suited for a wide range of air conditioning types such as single-split systems, packaged units or small central aircon units.

|

6. Interrupt compressor (or compressor contactor) switching wire. This is the cable through which the thermostat tells the compressor to run or stop

|

7. Route this wire through the AIRCOSAVER (i.e. the AIRCOSAVER is now logically in series with the thermostat). Connect power to the AIRCOSAVER.

|

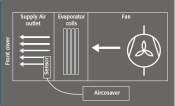

8. Position sensor in supply air stream (schematic)

|

9. Position sensor in air supply stream (example)

|

10. Replace covers

|

Congratulation! Installation is complete. Your AC system is ready to save energy.

Air-conditioning systems suitable for the AIRCOSAVER

The standard version is suitable for most residential and light commercial DX (direct expansion) AC systems, e.g. window units, wall-mounted units, single splits and small packaged units.

If you would like to use it on larger systems, industrial units or on different applications such as reverse cycle air conditioning (incl. heating) or cold storage cooling, please contact us for customized versions.

The standard AIRCOSAVER should not be used with chilled water systems, evaporative cooling systems, the latest inverter type split systems and multi split systems.

Please note: Installing and servicing air conditioning equipment can be hazardous due to system pressures and electrical components. Although AIRCOSAVER installation is quick and simple, it should only be conducted by trained electricians or HVAC contractors to ensure proper system setup and maximum savings

If you would like to use it on larger systems, industrial units or on different applications such as reverse cycle air conditioning (incl. heating) or cold storage cooling, please contact us for customized versions.

The standard AIRCOSAVER should not be used with chilled water systems, evaporative cooling systems, the latest inverter type split systems and multi split systems.

Please note: Installing and servicing air conditioning equipment can be hazardous due to system pressures and electrical components. Although AIRCOSAVER installation is quick and simple, it should only be conducted by trained electricians or HVAC contractors to ensure proper system setup and maximum savings

The AIRCOSAVER upgrading philosophy

Your satisfaction is our top priority. We would like to give you as much information as possible to enable you to make an informed choice. We would like to detail why installing an AIRCOSAVER makes sense and what can and can not be achieved.

Air conditioning is a major consumer of electrical power

In many of the warmer countries around the world air conditioning is one of the largest energy consumers in the residential and industrial sector. On a small scale air conditioning accounts for a large part of home and business owners' energy bills. Millions of simple air conditioning units waste unbelievable amounts of energy every day. Not only is the absolute power demand for air conditioning very high, but air conditioning also contributes to extreme peak energy demand on the hottest days of the year which the energy infrastructure has to cope with.

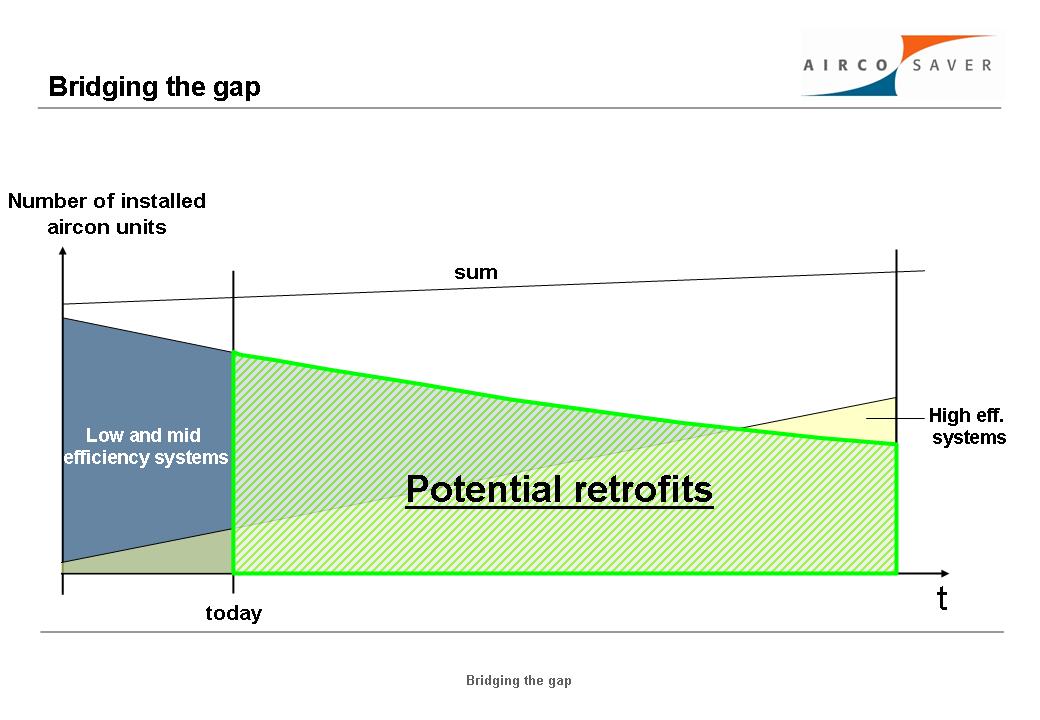

Yesterday's aircon technology will be around for many years

Our advice to any owner of a low efficiency window unit or single split system is "Replace your entire old system today and buy a new ultra-high efficiency system. Make sure it is dimensioned properly, that it is HCFC free and that it uses the most advanced compressor and control technology!"

No matter how desirable this kind of change is, reality is different!

There are millions of older systems in use. In 2001 the Intergovernmental Panel on Climate Change (IPCC) estimated that worldwide a total of over 289 million window/wall mounted units and unducted single split systems were in use. In addition, an increasing number of these types of systems is installed every year. In 2001 only for the mentioned types of systems this number was estimated to be almost 38 million, many of them still being low and mid efficiency units. The most efficient new air conditioning systems are simply too expensive for many applications and payback time is still too long. Besides, many countries still have not adopted high-efficiency standards for new systems.

So these simple units will be operating on a large scale for many years to come. They will not just go away. Nor will they be replaced quickly. Average equipment lifetime is typically twelve to fifteen years and in many cases much longer. However, usually these units are not considered for retrofits. Controller manufacturers usually prefer to focus on very large system where even small improvements can be sold for high prices.

Air conditioning is a major consumer of electrical power

In many of the warmer countries around the world air conditioning is one of the largest energy consumers in the residential and industrial sector. On a small scale air conditioning accounts for a large part of home and business owners' energy bills. Millions of simple air conditioning units waste unbelievable amounts of energy every day. Not only is the absolute power demand for air conditioning very high, but air conditioning also contributes to extreme peak energy demand on the hottest days of the year which the energy infrastructure has to cope with.

Yesterday's aircon technology will be around for many years

Our advice to any owner of a low efficiency window unit or single split system is "Replace your entire old system today and buy a new ultra-high efficiency system. Make sure it is dimensioned properly, that it is HCFC free and that it uses the most advanced compressor and control technology!"

No matter how desirable this kind of change is, reality is different!

There are millions of older systems in use. In 2001 the Intergovernmental Panel on Climate Change (IPCC) estimated that worldwide a total of over 289 million window/wall mounted units and unducted single split systems were in use. In addition, an increasing number of these types of systems is installed every year. In 2001 only for the mentioned types of systems this number was estimated to be almost 38 million, many of them still being low and mid efficiency units. The most efficient new air conditioning systems are simply too expensive for many applications and payback time is still too long. Besides, many countries still have not adopted high-efficiency standards for new systems.

So these simple units will be operating on a large scale for many years to come. They will not just go away. Nor will they be replaced quickly. Average equipment lifetime is typically twelve to fifteen years and in many cases much longer. However, usually these units are not considered for retrofits. Controller manufacturers usually prefer to focus on very large system where even small improvements can be sold for high prices.

|

Solution: Bridging the gap with a cost effective retrofit

We think that retrofitting these smaller units makes a lot of sense in terms of overall reduced energy usage and reduced operating costs. Retrofiting with the AIRCOSAVER can bridge the gap and lower energy consumption considerably until new high efficiency system become more widespread. The AIRCOSAVER has been designed as an affordable and practical device with short payback times. |

Savings mechanism of the AIRCOSAVER

As engineers we do not believe in miracles and we are sure you don't, either. When we began designing a controller specifically for retrofit purposes, we conducted a lot of research and experimented with various principles (more details here). We also came across all sorts of "unique" devices and "black boxes" that claim phantastic energy savings.

Over time we became deeply persuaded that the most effective and practical method to create significant savings with the smallest tradeoffs in cooling comfort is to determine the system's current thermodynamic efficiency and switch the compressor off, when it is evidently inefficient. This is logical since the compressor typically acccounts for 80% of the system's energy consumption. This, in combination with protecting the compressor against potentially harmful short cycling led to the AIRCOSAVER. We think that out of all retrofit solutions and out of all proposed cycling methods this is the most effective with the smallest costs in cooling comfort.

Limitations of any retrofit

No retrofit will do miracles. With a given system there is always a limit to the possible improvements in energy efficiency. A number of factors are fixed such as the type and efficiency of the refrigerant in the system. Other factors can be optimized such as the runtime of the compressor. A retrofit will not remedy major planning mistakes or technical faults in your system.

Potential tradeoffs of installing an AIRCOSAVER

Installing an AIRCOSAVER can slightly alter the cooling characteristics of your system. With an AIRCOSAVER installed, inefficient overcooling is avoided. This is desired, since a lot of energy is wasted in this stage, but it may result in slightly higher average evaporator coil temperatures since the savings algorithm also provides an anti short cycling protection for your system.

In consequence this may have two effects. Firstly, the set point may be reached slightly slower without the wasteful overcooling. However, overshoot of the set temperature is reduced as well. Cooling cycles become more gradual. This is often considered very beneficial in terms of cooling comfort by residents.

Secondly, the dehumidifaction capacity of your your system may decrease slightly. In extremely wet climates this can potentially be a drawback. On the other hand, many customers have reported that the AIRCOSAVER has incresased cooling comfort because a certain degree of humidity contributes to the subjective wellbeing in a room. There are various simple air conditioning units that by overcooling make the room air excessively dry.

In relation to the benefits, we consider these potential drawbacks as minor for a wide range of applications. Numerous case studies and independent measurement have demonstrated that these changes - although measureable - have very little impact on the overall cooling performance.

What the AIRCOSAVER can not achieve

The AIRCOSAVER can not compensate for deficiencies in the original system. For example, if your aircon system is poorly serviced and does not cool properly in the first place, then the AIRCOSAVER will not change this.

Secondly, if an aircon unit is clearly undersized for a given application (too small for the heat load) and the compressor runs for very long periods but the thermostat set temperature is never achieved, then the AIRCOSAVER will not remedy this, either.

In conclusion, we recommend to check 2 things before installing an AIRCOSAVER

What the AIRCOSAVER can achieve

An AIRCOSAVER will improve the overall energy efficiency of your system. Typical energy savings are up to 30%. Generally these savings come at very small, hardly noticeable decreases in cooling comfort. It uses the the circuitry and switches available in (and designed for) your system and does not require replacement of electronic components. The AIRCOSAVER just adds one control dimension (thermodynamic saturation) to your system and compensates your system's deficits.

Overall assessment

Weighing the potential small tradeoffs against the significant energy savings, we think that the AIRCOSAVER is the optimum measure for achieving a significant improvement in energy efficiency. Furthermore, these savings come at an affordable and reasonable cost which will result in a short payback period.

As engineers we do not believe in miracles and we are sure you don't, either. When we began designing a controller specifically for retrofit purposes, we conducted a lot of research and experimented with various principles (more details here). We also came across all sorts of "unique" devices and "black boxes" that claim phantastic energy savings.

Over time we became deeply persuaded that the most effective and practical method to create significant savings with the smallest tradeoffs in cooling comfort is to determine the system's current thermodynamic efficiency and switch the compressor off, when it is evidently inefficient. This is logical since the compressor typically acccounts for 80% of the system's energy consumption. This, in combination with protecting the compressor against potentially harmful short cycling led to the AIRCOSAVER. We think that out of all retrofit solutions and out of all proposed cycling methods this is the most effective with the smallest costs in cooling comfort.

Limitations of any retrofit

No retrofit will do miracles. With a given system there is always a limit to the possible improvements in energy efficiency. A number of factors are fixed such as the type and efficiency of the refrigerant in the system. Other factors can be optimized such as the runtime of the compressor. A retrofit will not remedy major planning mistakes or technical faults in your system.

Potential tradeoffs of installing an AIRCOSAVER

Installing an AIRCOSAVER can slightly alter the cooling characteristics of your system. With an AIRCOSAVER installed, inefficient overcooling is avoided. This is desired, since a lot of energy is wasted in this stage, but it may result in slightly higher average evaporator coil temperatures since the savings algorithm also provides an anti short cycling protection for your system.

In consequence this may have two effects. Firstly, the set point may be reached slightly slower without the wasteful overcooling. However, overshoot of the set temperature is reduced as well. Cooling cycles become more gradual. This is often considered very beneficial in terms of cooling comfort by residents.

Secondly, the dehumidifaction capacity of your your system may decrease slightly. In extremely wet climates this can potentially be a drawback. On the other hand, many customers have reported that the AIRCOSAVER has incresased cooling comfort because a certain degree of humidity contributes to the subjective wellbeing in a room. There are various simple air conditioning units that by overcooling make the room air excessively dry.

In relation to the benefits, we consider these potential drawbacks as minor for a wide range of applications. Numerous case studies and independent measurement have demonstrated that these changes - although measureable - have very little impact on the overall cooling performance.

What the AIRCOSAVER can not achieve

The AIRCOSAVER can not compensate for deficiencies in the original system. For example, if your aircon system is poorly serviced and does not cool properly in the first place, then the AIRCOSAVER will not change this.

Secondly, if an aircon unit is clearly undersized for a given application (too small for the heat load) and the compressor runs for very long periods but the thermostat set temperature is never achieved, then the AIRCOSAVER will not remedy this, either.

In conclusion, we recommend to check 2 things before installing an AIRCOSAVER

- Only install an AIRCOSAVER on systems that are cooling properly in the first place. Make sure that the aircon unit is in a decent service state (e.g filters should be clean and not blocked). You could also measure the supply air temperature with a small thermometer prior to installation. If this does not fall significantly below 20 degrees Celsius, DO NOT install an AIRCOSAVER.

- Check if the aircon unit reaches the thermostat in normal operational conditions. If an aircon unit is clearly undersized (i.e. the thermostat temperature is never reached and the compressor simply runs all day) then DO NOT install an AIRCOSAVER. In these instances there are physically no savings possible anyway and the AIRCOSAVER learning phase (until it has understood that the thermostat can never be reached) can result in higher room temperatures. So this situation should be excluded.

What the AIRCOSAVER can achieve

An AIRCOSAVER will improve the overall energy efficiency of your system. Typical energy savings are up to 30%. Generally these savings come at very small, hardly noticeable decreases in cooling comfort. It uses the the circuitry and switches available in (and designed for) your system and does not require replacement of electronic components. The AIRCOSAVER just adds one control dimension (thermodynamic saturation) to your system and compensates your system's deficits.

Overall assessment

Weighing the potential small tradeoffs against the significant energy savings, we think that the AIRCOSAVER is the optimum measure for achieving a significant improvement in energy efficiency. Furthermore, these savings come at an affordable and reasonable cost which will result in a short payback period.

Other principles used in energy savings controls

As engineers we do not believe in miracles and we are sure you don't, either. During the development of the Aircosaver we conducted a lot of research and experimented with various principles that provide energy savings in other applications. We would like to share some of these insights with you.

We also came across all sorts of "unique" devices and "magical black boxes" that claim to save energy, which we will not comment further. Please be adequately suspicious and make sure you really understand what they do before spending large amounts of money.

1. Induction motor controls, power factor correctors

For many years devices have been around that aim to optimize the operation of induction motors which frequently run on partial loads. The basic concept was invented by Frank Nola of NASA in the late 70's. The aim was to reduce energy wastage on small single phase induction motors. Basically, these devices monitor the difference between kw and kVA drawn by an electrical consumer. Based on this difference, they then try to match the motor better to the load, e.g. by reducing voltage. This in turn reduces the magnetizing current and the iron losses and in turn improves the power factor (this then leads to some other, often detrimental effects).

There is a range of products available that all claim to be truely unique. This principle is employed by the controllers you can get from companies like Somar, Savawatt or Power Efficiency Corp.

Besides that there are devices available that combine power factor correction with a delay in power supply during each phase (like a phase cut-off dimmer), also termed "energy modulation devices". Each sine wave is delayed for a small amount of time (few miliseconds) when passing through zero voltage. So a small part of each sine wave is basically chopped off.

We also came across all sorts of "unique" devices and "magical black boxes" that claim to save energy, which we will not comment further. Please be adequately suspicious and make sure you really understand what they do before spending large amounts of money.

1. Induction motor controls, power factor correctors

For many years devices have been around that aim to optimize the operation of induction motors which frequently run on partial loads. The basic concept was invented by Frank Nola of NASA in the late 70's. The aim was to reduce energy wastage on small single phase induction motors. Basically, these devices monitor the difference between kw and kVA drawn by an electrical consumer. Based on this difference, they then try to match the motor better to the load, e.g. by reducing voltage. This in turn reduces the magnetizing current and the iron losses and in turn improves the power factor (this then leads to some other, often detrimental effects).

There is a range of products available that all claim to be truely unique. This principle is employed by the controllers you can get from companies like Somar, Savawatt or Power Efficiency Corp.

Besides that there are devices available that combine power factor correction with a delay in power supply during each phase (like a phase cut-off dimmer), also termed "energy modulation devices". Each sine wave is delayed for a small amount of time (few miliseconds) when passing through zero voltage. So a small part of each sine wave is basically chopped off.

The manufacturers of power factor devices frequently claim that air conditioners have low power factors. During development we measured the power factor of some units. At least the ones we have tested were already compensated internally very well. So no improvement potential here. Even our cheap Hitachi window unit has a power factor of 1.0 with maximum deviations to 0.99 inductive and 0.99 capactitive.

Our comment: Certain savings are possible with this principle if devices really are compensated badly or if supply power quality is very bad. Savings have been demonstrated, especially where oversized induction motors run idle for a long time such as in injection moulding machines. Most major companies that used to employ this technology have dropped it (Siemens, GE, etc.) because savings in typical applications were usually significantly smaller than expected. The available market prices for these devices lead to very long payback times. We could not make out any potential for typical air conditioners since they are usually compensated quite well. For very interesting discussions on these products go here or read this analysis.

Our comment: Certain savings are possible with this principle if devices really are compensated badly or if supply power quality is very bad. Savings have been demonstrated, especially where oversized induction motors run idle for a long time such as in injection moulding machines. Most major companies that used to employ this technology have dropped it (Siemens, GE, etc.) because savings in typical applications were usually significantly smaller than expected. The available market prices for these devices lead to very long payback times. We could not make out any potential for typical air conditioners since they are usually compensated quite well. For very interesting discussions on these products go here or read this analysis.

2. Inverters, variable speed drives (VSD)

Induction motors as they are typically used for compressors and fans in air conditioning systems, are limited to a very narrow range of speeds, they are basically fixed-speed motors. Their speed is determined by the constant frequency of the power supply (typically 50 or 60 Hz).

Inverter controls enable the fixed-speed motor to operate at variable speeds. The combination of motor and control unit is then termed "Variable speed drive". Inverter controls are usually used on three-phase AC (alternating current) motors but can also be used on some single-phase AC motors. These controls use rectifiers to create an intermediate DC voltage out of the AC supply voltage. Out of the DC voltage the inverter then generates an AC output signal of varying frequency and voltage to the compressor. Most modern controls use pulse width modulation for the output voltage. Filtering harmonics and electromagnetic compatibilty are typical issues that need to be taken care of, but modern inverter systems have made significant progress in this respect.

Variable frequency controllers are probably the most effective controllers available today. However, to create a good system, the controller needs to be matched carefully to the load and the whole system should be designed with this approach. That's what makes inverter controls rather expensive and difficult to retrofit. Whether an inverter control can be fitted or not needs to be examined in regards to the specific system. This in combination with the high cost is why inverter retrofits are usually only conducted as one-offs on large systems.

Our comment: Way to go!

Variable frequency drives are very effective energy savers. When replacing your old system with a new one, you should definitely buy a high-efficiency system including inverter controls. Very similar to the implementation in the AIRCOSAVER, these controls use sensors to define load and current efficiency of the aircon system and establish a control loop. Where the AIRCOSAVER switches the compressor off, the inverter will reduce the speed of the compressor (and potentially fans) to a lower level. Inverter systems are still clearly more expensive than other systems, but this will pay off over the system's lifecycle. Retrofits only make sense for large systems and feasibility needs to be judged specifically for each unit.

3. Static duty cycling and various other cycling methods

In static duty cycling the aircon unit (compressor and/or fan) is cycled on a predetermined (fixed) pattern on and off. The background for this technique mainly lies in demand side management in terms of load shifting and peak demand reduction. Other duty cycling devices try to prolong the on and/or off periods based on monitoring thermostat calls. Several other methods have been proposed.

Our comment:

These principles can save some energy but savings usually come at the cost of a significantly reduced cooling comfort since current efficiency is not taken into account.

4. Other devices

Induction motors as they are typically used for compressors and fans in air conditioning systems, are limited to a very narrow range of speeds, they are basically fixed-speed motors. Their speed is determined by the constant frequency of the power supply (typically 50 or 60 Hz).

Inverter controls enable the fixed-speed motor to operate at variable speeds. The combination of motor and control unit is then termed "Variable speed drive". Inverter controls are usually used on three-phase AC (alternating current) motors but can also be used on some single-phase AC motors. These controls use rectifiers to create an intermediate DC voltage out of the AC supply voltage. Out of the DC voltage the inverter then generates an AC output signal of varying frequency and voltage to the compressor. Most modern controls use pulse width modulation for the output voltage. Filtering harmonics and electromagnetic compatibilty are typical issues that need to be taken care of, but modern inverter systems have made significant progress in this respect.

Variable frequency controllers are probably the most effective controllers available today. However, to create a good system, the controller needs to be matched carefully to the load and the whole system should be designed with this approach. That's what makes inverter controls rather expensive and difficult to retrofit. Whether an inverter control can be fitted or not needs to be examined in regards to the specific system. This in combination with the high cost is why inverter retrofits are usually only conducted as one-offs on large systems.

Our comment: Way to go!

Variable frequency drives are very effective energy savers. When replacing your old system with a new one, you should definitely buy a high-efficiency system including inverter controls. Very similar to the implementation in the AIRCOSAVER, these controls use sensors to define load and current efficiency of the aircon system and establish a control loop. Where the AIRCOSAVER switches the compressor off, the inverter will reduce the speed of the compressor (and potentially fans) to a lower level. Inverter systems are still clearly more expensive than other systems, but this will pay off over the system's lifecycle. Retrofits only make sense for large systems and feasibility needs to be judged specifically for each unit.

3. Static duty cycling and various other cycling methods

In static duty cycling the aircon unit (compressor and/or fan) is cycled on a predetermined (fixed) pattern on and off. The background for this technique mainly lies in demand side management in terms of load shifting and peak demand reduction. Other duty cycling devices try to prolong the on and/or off periods based on monitoring thermostat calls. Several other methods have been proposed.

Our comment:

These principles can save some energy but savings usually come at the cost of a significantly reduced cooling comfort since current efficiency is not taken into account.

4. Other devices

Recently we also analysed a Chinese product which claims to save 25% to 35% of energy. We were quite amused once we figured out how this device is supposed to work. Take a look at the picture. The little silver box is not a temperature sensor but it is a heating(!) element. This little silver box is placed over the aircon unit's thermostat sensor! The thermostat sensor is then heated up inside the silver box... We measured temperatures of up to 50 degrees celsius on the surface of the heating element. Go figure.

Our comment:

It's probably easier and cheaper to simply turn up your thermostat by 10 degrees.

Our comment:

It's probably easier and cheaper to simply turn up your thermostat by 10 degrees.